Customer Service

October 21, 2022

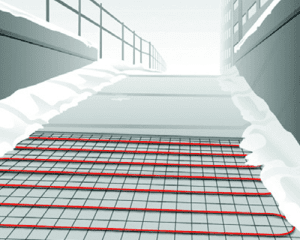

The arrival of winter means pipelines and industrial processes will once again be the target of freezing temperatures. Heat tracing circuits allow you to solve much, if not all of your problems. Proper use of heat cables can help prevent corrosion, loosening of electrical components, and water ingress. nVent heat tracing cables are reliable, simple in design, fast and easy to install.

All ground fault breakers should be tested according to the manufacturer’s instructions.

Damaged or improperly installed components can result in water ingress, corrosion or the loosening of electrical connections.

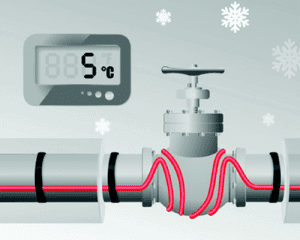

A thermostat or controller will allow you to optimize your energy usage while keeping your process running at a temperature be the winter season

Insulation plays a critical role in the overall heat tracing system. No insulation or wet insulation reduces heat transfer from the heating cable to the pipe and can render electric heat tracing completely ineffective.

Visually inspect the conduit distribution system for openings in conduit, damaged or missing components and low-point drains.

Stocking spare components and cables will allow for timely repairs or replacements in case of an emergency. All installation & maintenance manuals can direct you in the repair or replacement of heat tracing system components.

Complete installation and maintenance records will allow you to verify what system tests have been completed, the original electrical values, etc. This information can be valuable in determining if the system is operating properly over time.

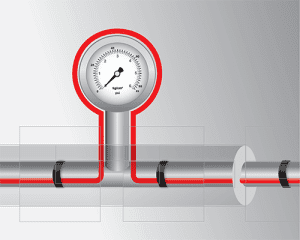

Instrument Heating

Pipe Freeze Protection

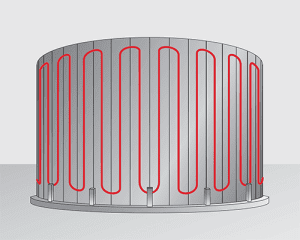

Tank Heating

Cable basket trays are more cost efficient, reliable, adaptable to change, and easy to maintain. Order your cable trays to protect your wiring…

Buy MOGAS to solve issues that routinely plague power plants – leaking valves, seat erosion, blown packing, and the inability to isolate critical…

Everything you need to shop for a Rittal Enclosure: from selecting the enclosure and cooling system to power distribution and…

Customer Service

1.888.467.7626