Customer Service

August 6, 2024

Understanding the different classifications for hazardous locations is crucial for safety at your worksite. What exactly do Class, Zone, and Division mean? Let’s dive in and take a closer look.

A hazardous location is an area that has the potential for fire or explosion, whether due to the presence of flammable gases, vapours, dust, or fibres, and where special precautions and equipment are necessary.

Examples of hazardous locations include grain elevators and mills, oil refineries, mines, textile mills, and chemical manufacturing facilities.

The Canadian Electrical Code (CEC) outlines specific categories to help identify and manage these risks, known as Class, Zone, and Division. Each one is defined by the type of hazardous material present and risk level.

But there are further specifications based on location and industry. For example, in locations with risk of fire, the National Fire Code of Canada addresses fire safety in buildings, including for electrical installations in hazardous locations.

As well, each province can adopt and modify the CEC to suit local requirements, such as under the Alberta Electrical Utility Code. Be sure to know which codes apply in your area.

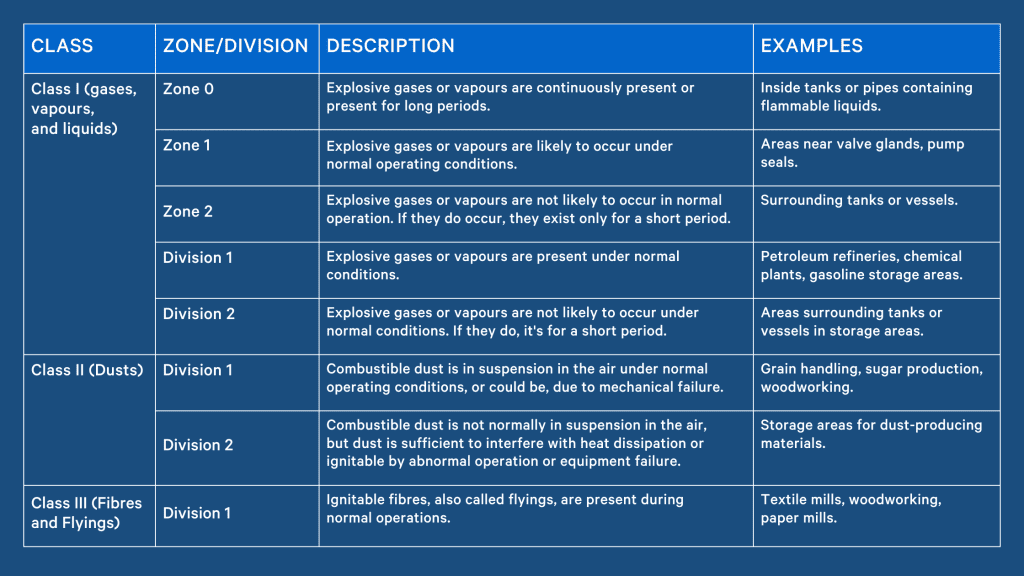

Hazardous locations are categorized into three main classes—each defined by the type of hazardous material present and associated risks.

This category includes places where flammable gases, vapours, or liquids are present, with a risk of creating explosive atmospheres when mixed with air. Examples are petroleum refineries, chemical plants, and gasoline storage areas.

Class 1 locations can be subdivided into zones (Zone 0, Zone 1, or Zone 2) or divisions (Division 1 and Division 2), depending on specific circumstances and risks.

These are areas where combustible dust could accumulate and create explosive atmospheres. Industries such as grain handling, sugar production, and woodworking often have Class II hazardous locations. Class II locations typically use divisions (Division 1 and Division 2).

These include spaces where ignitable fibres, or flyings, are present—such as textile mills, wood shops, and paper mills. While fibres are not typically in the air, they can accumulate around machinery or equipment. Class III locations also use divisions (Division 1 and Division 2).

Hazardous locations in Canada are sub-divided into zones or divisions, as outlined in the CEC. These sub-categories provide more specific information about the risk and conditions of a particular hazardous location.

Used mainly for Class I locations,the zone classification system is based on the frequency and duration of explosive gases or vapours. You’ll need to apply this more recent and internationally harmonized system for all new construction. This system is also especially useful for complex environments where detailed risk assessment is necessary.

Divisions are used in Class I, II, and III locations. A broader classification system, divisions are often used in less complex environments. This older method is still applied and may be used during maintenance or repair work in your building.

Below is a table outlining how classifications interact with zones and divisions depending on potential hazards and location examples.

Note: you can’t mix zones and divisions within a single class location—they are separate systems for defining risks within classes.

Some common industry environments here in Canada are mills, mines, and marine locations. But how do you typically classify these?

In addition to Class I and Class II, the CEC includes zones for areas where combustible dust or fibres are present. These are commonly applicable to mills, mines, and marine environments.

Grain-handling areas might be classified under Zone 20, which is where combustible dust or fibres are present continuously or for long periods, making them high-risk areas. Explosive dust atmosphere in the air in occasional clouds—or Class II, Division 2—hazardous dust clouds may occur during abnormal operation—due to the presence of combustible grain dust.

Similar to grain-handling areas, flour mills may also fall under Zone 20 or Class II, Division 2 due to the risk of flour-dust explosions.

Be mindful that different zones or divisions often exist at the same location. For example, a flour mill might be classified Zone 20 for its flour-handling area, while its office area is a safe zone.

Depending on the presence of methane gas or coal dust, underground tunnels could be classified as Zone 0 or Zone 1—explosive gas atmosphere present continuously or occasionally.

They could also fall under Class I, Division 1 or Class II, Division 1—hazardous atmosphere or dust cloud present continuously or periodically.

Knowing about hazardous locations is also important for marine transportation, a common hazardous location on the coasts of Canada.

Engine rooms and fuel-storage areas are likely to be classified as Zone 0—continuous explosive gas atmosphere. They could also be under Class I, Division 1—hazardous atmosphere present continuously—due to vapours from gasoline, diesel, or other flammable liquids.

To prevent accidents, injuries, and potential disasters, there are some key safety precautions to follow.

To better understand your specific location, conduct a thorough risk assessment to identify hazards and accurately classify your area. Only use equipment that’s properly rated equipment as classified.

Ensure that your staff is well-trained and educated on both hazards and necessary safety protocols. Regulations change often, so follow industry experts or contact experienced professionals to educate staff with accurate information.

Regular maintenance and equipment inspections will help you maintain safety standards and ensure all systems function correctly.

Ensure that ventilation systems are operating smoothly to keep locations well-ventilated and disperse hazardous gases, vapours, and dust accordingly.

Proper lighting is crucial. But make sure to use lighting brands and products that are designed specifically for hazardous locations, such as ABB’s Hazlux® line. This high-quality, industrial line is known for specializing in enhancing visibility and reducing risk in hazardous locations in harsh conditions.

Rely on advice from industry professionals, and always source quality products from renowned suppliers and trusted distributors.

Getting to know these categories will help you ensure proper safety measures and compliance when flammable gases, vapours, dust, or fibres are present at a work site.

For more detailed information, refer to the latest edition of the CEC. And be sure to consult with qualified electricians to determine the appropriate classification for your environment.

Customer Service

1.888.467.7626