Customer Service

October 20, 2022 | ABB Hazlux

Hazardous Location Site that is open 24 hours a day/365 days a year

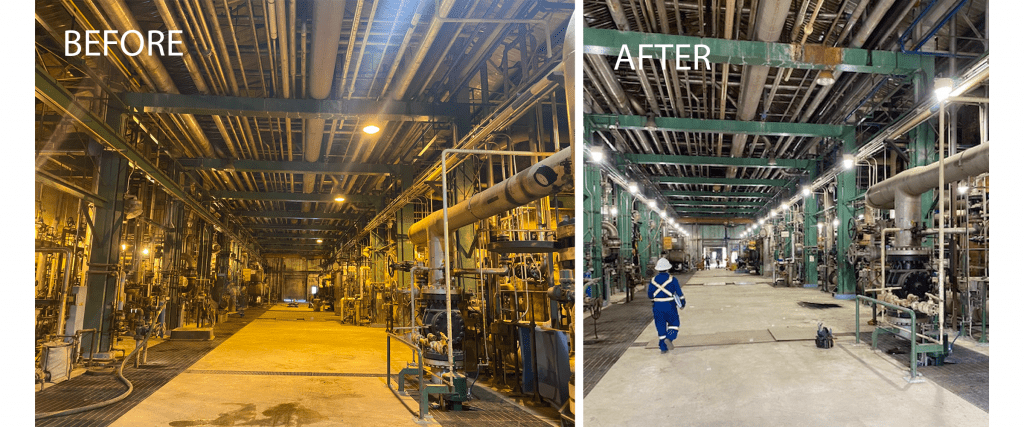

The Hazlux Lighting Fixture can be seen in action with this impressive Before & After image of the site.

The lighting team at E.B. Horsman can provide your project with incentive estimates, calculate R.O.I. and payback periods through auditing software, perform lighting calculations and configure control systems for any lighting system at your facility.

The ABB Hazlux® luminaires are known as high quality industrial lighting fixtures designed, tested and certified for use in hazardous locations and adverse environment conditions. Specifiers and distributors rely on Hazlux® to safely provide light where it’s needed — even under the harshest indoor and outdoor conditions.

You can rely on Hazlux® to safely provide light where you need it, even under the harshest indoor and outdoor conditions. If safety, labor reduction, quality and reliability are your priorities, consider Hazlux® lighting products to reduce maintenance and prevent downtime.

When you’re looking for hazardous location lighting, you need an experienced partner you can trust. Someone who will accompany you every step of the way and provide expert advice and exceptional service. The ABB sales team has been doing just that for close to a century

Engineering expertise at your fingertips

ABB and E.B. Horsman product specialists and engineers are readily available to answer all your technical questions, and partner with you in selecting the best lighting solution to reach your goals.

High standards of quality control

Quality is built into every product at every step of the process, from design to final assembly. Each product is inspected and tested to ensure that it meets our strict quality standards, and then professionally packed so that your order will arrive intact at your installation site.

Product customization

ABB design and manufacture units, giving us unparalleled capabilities to customize lighting fixtures to meet your specific needs.

Reduced lead time

ABB produces what you need when you need it in their state-of-the-art North American Center of Excellence, located in Quebec. They can easily accommodate both large and small production runs with a fast turnaround.

Hose-down and wet locations • Certified for wet locations

– NEMA 4X, IP65, IP66, IP67/68 (indoor and outdoor); CSA and cULus Listed

• Superior gasketing system – both tank and globe gasketing systems withstand hose-down pressures

• Uninterrupted globe thread – assures positive seal

• Baked-on, dry epoxy coating – not paint but 100% dry solids

• Globes, refractors and finish designed to withstand thermal shock during hose down

High-ambient temperature areas

• All standard fixtures are tested and listed for at least 104°F (40°C) ambient – even under heavy dust blanket and no air flow

• Exclusive heat sink design results in a cool operating fixture, extended ballast/lamp life and lower maintenance costs

• Selection of high-ambient temperature rated fixtures – contact your ABB representative for fixtures certified for 131°F (55°C) and 149°F (65°C) applications

• Steam spray and thermal shock resistant

Corrosion and abrasion

• Baked-on, dry epoxy coating – not paint but 100% dry solids

• Stainless steel external hardware

• Sand-blast resistant finish

• Superior silicone gasketing system on both tank and globe (other gasketing systems available for special corrosive applications such as phosphates)

• Aluminum components contain less than 0.4% copper for maximum corrosion resistance

• Special HazCote® corrosion fighter finish available for extremely corrosive areas; consult your EBH representative for details

Ice and arctic conditions

• Gasketing system and finish allow for expansion and contraction through wide temperature variations

• High-strength mechanical mountings withstand ice loading

• Tempered glassware available for extra thermal shock safety margin

Vibration and vandalism

• Vibration tested by UL and CSA

• Vibration-resistant hardware throughout fixture

• Screw retainers on guard ensure retention even if screws are not completely tightened

• Vibration-resistant globe thread and sealing system

• Optional refractors, high-strength tempered glass and Teflon®-coated globes for protection from vandalism

Dust blanket

• Tested and listed by UL and CSA

• Cone pendant mount available (45° sloped sides) for areas where dust or other residue buildup is a problem

• Exclusive heat sink design – results in a cool operating fixture, extended ballast/lamp life and lower maintenance costs

Wind

• Wind-tunnel tested at McDonnell Douglas Corporation at air flow speeds in excess of 320 km/h (198 mph)

• Guard specially designed to secure reflector during high wind loading

• High-strength mechanical mountings withstand strong wind loads

A wide range of products and features are available to suit the needs of specific hazardous locations. Consider the requirements of each space to select the best lighting fixtures:

• Average footcandles

• Average mounting height

• Lumen output required for the space

• Optics

• Type and number of units

Choosing the right hazardous location luminaire doesn’t have to be complicated. Just start by thinking about what type of conditions you have and what features are important to you. Then contact an E.B. Horsman lighting specialist. It’s that simple!

Shop datacom products recommended by our experts for fast, secure, reliable, & professional video...

Read our guide to fiber termination learn why it’s needed, common methods to terminate fiber, concerns and our...

In copper connectors copper is used to carry a signal within a limited distance & bandwidth. It is the most economical option & already exists in many...

Customer Service

1.888.467.7626