Customer Service

October 18, 2017

We exist in a world of interconnectivity where communications-capable machinery can function either autonomously or with minimal human interaction. The backbone of the interconnectivity is complex industrial communication networks which utilize communication protocols that have evolved over time.

Industrial automation system architecture must rely on these robust communication networks to achieve further digital transformation of plant floor processes. They are required for data exchange, data control, and the flexibility to connect devices or machines from different manufacturers in the same installation.

Some common controllers used for industrial automation architecture are: PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), and DCS (Distributed Control System). They interface and control field devices, distributed IO systems/controllers, HMIs, and supervisory PCs.

What is Industrial Communication?

Data communication is the conversion and transmission of information, often in a digital format, from a transmitter to a receiver through a link (copper, coax, optical fiber or wireless). Industrial Communication Networks are designed and built to handle real-time control and data integrity while installed in large plants that are potentially operating in harsh environments.

Regardless of link type (copper, coax, fiber or wireless), these networks allow the exchange of large amounts of data while using limited bandwidth. There are various ways to implement a communication structure depending on the required communication protocols of digital controllers, field devices, dedicated automation software, and external systems. Maintaining overall system connectivity and reliability is necessary therefore; Open Systems Interconnection (OSI) standards are becoming the new trend in industrial communications.

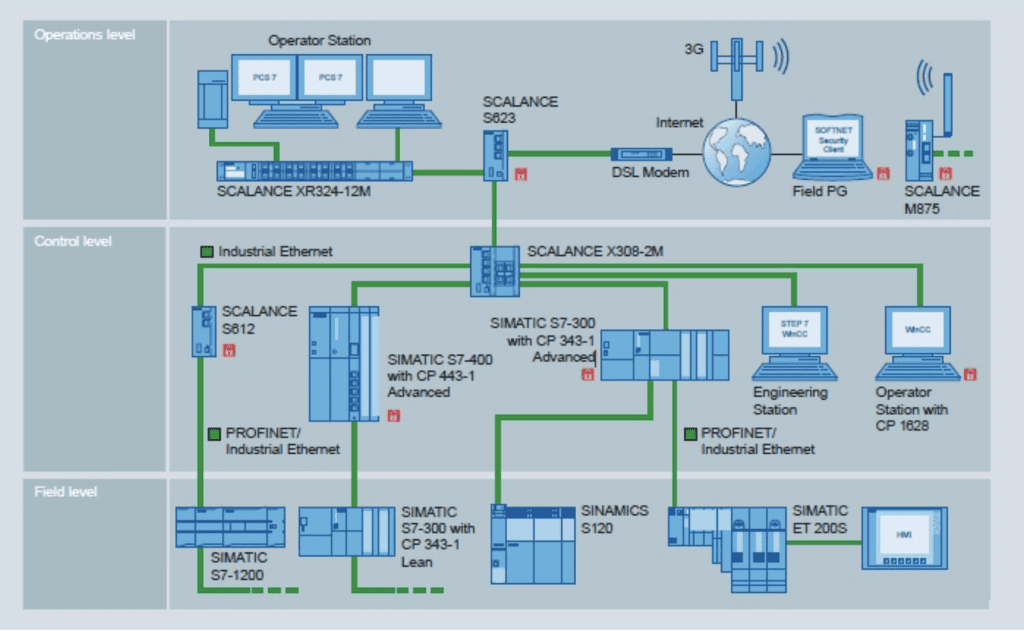

A vertical network is typically used in manufacturing and/or process industry where data exchange is bidirectional between field level devices and operations management level infrastructure.

Devices operating at this level typically utilize on/off signals, 4-20mA current loops, or serial point-to-point communication options. The most sophisticated communication technology used at this level is a fieldbus (e.g. ProfiNET, Profibus, HART, ControlNet, DeviceNet, CAN Bus, and Foundation Field Bus), which allows for distributed control among smart field devices and controllers. An Unmanaged Ethernet Switch is an example of an industrial device operating at the Field Level. Depending on the physical layout, Unmanaged Ethernet Switches may also require built-in media converters (copper to optical fiber).

This level consists of PLCs and Operator Interfaces. For instance, fast response times, quick transmission rates, synchronization between machines, processing of critical data, and minimal data volumes are specific characteristics of this level.

LAN (Local Area Network) utilizing Ethernet TCP/IP communication protocol for connecting control units with computers is an example of proper network architecture for the Control Level. This type of network is also suitable for coordination and synchronization between controller units (acting as a control bus). Managed Ethernet Switches typically operate at this level for advanced configuration and increased network control. In Managed Ethernet Switches, each port can be configured individually, different levels of user access can be employed, and connections can be closely monitored in terms of traffic throughput, errors, and port status. They usually have a Web Interface for remote access, which allows network administrators to make changes remotely.

This level resides at the top of industrial automation systems collecting information from its direct lower level (Control Level – Layer 2). Usually, it handles large volumes of data that are not time sensitive. Common network architecture at this level is an Ethernet LAN suitable for the large scale of these networks and their scope (factory planning and management information exchange). It is common to connect these types of networks to other industrial networks using gateways.

Managed Ethernet Switches can also operate at this level (same as Layer 2).

Scalance is a complete range of Ethernet switches including cost-effective solutions for small networks to redundant network technology. It is also available with optional advanced diagnostics features and/or hazardous location or marine certification. Configuration software is not needed as all settings in the switches’ managed devices use the webserver. Siemens Ethernet switches serve the most demanding applications through innovative solutions based on proven standards. The Scalance family of Ethernet switches is defined by advanced features, robustness, and performance in every detail.

RuggedCom is recommended for applications in harsh environments where robustness and reliability are paramount. RuggedCom products are suitable for mission-critical networks such as substation automation, self-healing power grids and/or “Smart Grid” systems, traffic management for intelligent traffic systems, railway control systems, as well as process control and au

Turck Industrial Ethernet Switches offer two product series (IP20 and IP67), which makes them suitable for installation either in control cabinets (IP20) or directly in the field or on equipment (IP67). Both series are available in managed or unmanaged configurations with a variety of port configurations.

Compatible with most prominent PLC brands, eWON remote solutions are designed and built with security at heart. eWON’s VPN routers and tools provide easy remote access to PLC and SCADA systems, and data services and management. Information integrity, confidentiality, and availability are guaranteed using a layered security approach (aka Defense in Depth Approach).

Weidmüller provides a variety of communication solutions ranging from managed to unmanaged switches, wireless solutions, tools, connectors, and media converters. Meeting your specification requirements and/or preference with a trusted brand such as Weidmüller can be fulfilled.

Red Lion N-Tron rounds out our solution providers with a variety of options ranging from managed to unmanaged switches, available in a variety of port configurations. Meeting your specification requirements and/or preference with trusted brands like N-Tron can easily be achieved.

Cable basket trays are more cost efficient, reliable, adaptable to change, and easy to maintain. Order your cable trays to protect your wiring…

Buy MOGAS to solve issues that routinely plague power plants – leaking valves, seat erosion, blown packing, and the inability to isolate critical…

Everything you need to shop for a Rittal Enclosure: from selecting the enclosure and cooling system to power distribution and…

Customer Service

1.888.467.7626