Customer Service

Raise your glasses and join the worldwide celebration of hops, malt, and yeast on International Beer Day! This annual event, observed on the first Friday of August, unites beer enthusiasts from every corner of the globe in a toast to the rich and diverse world of brewing. Whether you’re a connoisseur or just enjoy the occasional pint, International Beer Day is the perfect occasion to immerse yourself in the flavours, traditions, and social camaraderie that make beer an integral part of our culture.

As we raise our glasses to toast the occasion, it’s equally important to appreciate the intricate process that goes into brewing the perfect pint. Behind the scenes, breweries rely on advanced process instrumentation products to ensure precision, consistency, and quality throughout the brewing process.

Breweries may have variations in their processes, depending on their specific equipment, beer styles, and brewing techniques. However, the general process of making beer involves several key steps.

The brewing process initiates with malting, wherein grains are soaked in water, rested in a controlled environment of humidity and temperature, and allowed to germinate. Subsequently, the germinated grains are dried and crushed, resulting in malt.

Malt is then roasted at various temperatures and durations, yielding an array of color and flavor characteristics. Distinct beers necessitate varying quantities of multiple roasted malts to form the desired profile, known as a Grist. These grains are crushed similarly to rolled oats, and in some Ales, oats, rye, or wheat may also be added.

The grist is introduced to a “mash tun” with water, and the temperature is regulated to activate alpha-amylase and beta-amylase enzymes, which break down the starches into different sugars. The resulting liquid, called “sweet wort,” is drained off, and the grains may be rinsed or “sparged” to achieve the desired brix for the intended style.

The sweet wort is then transferred to the kettles and boiled while various hop varieties are added at different times to create the distinct flavour, aroma, and bitterness profile of the style.

Once the wort is no longer sweet but rather ready for fermentation, it is pumped through a chiller to rapidly decrease the temperature and transferred into fermentation tanks, where yeast is added. The yeast consumes the sugars, producing alcohol, esters, and gases, which can be vented off or collected for other uses. Maintaining precise temperature during fermentation is crucial to avoid spoiling the batch.

Following fermentation, the ales move to “bright” tanks where they are clarified and carbonated with compressed CO2.

The final step involves packaging the beer for distribution and consumption, which may include bottling, canning, or kegging, along with labeling and packaging design.

Festo provides a wide range of products and services, including pneumatic and electric actuators, valves, sensors, controllers, and handling systems. Their automation solutions are utilized in various industries, such as manufacturing, automotive, electronics, food and beverage, and more. Festo is known for its commitment to research and development, constantly striving to develop cutting-edge technologies to enhance industrial automation and efficiency.

In numerous craft brew applications, the use of steam, hot water, or cleaning solutions is essential. To comply with regulations, vessels, kegs, and brewing equipment must undergo regular sterilization. When it comes to controlling the flow of liquids and gases, an angle seat valve proves to be the ideal choice. Its simplicity in design, cost-effectiveness, and ease of installation make it a popular option. Additionally, this valve is well-suited for a broad range of temperatures and can handle various media, even those with different degrees of contaminants.

Festo VZXF angle seat valve

In breweries, compressed air often serves as pilot air to control valves and cylinders. However, when used as process air, significantly higher levels of purity are necessary. Typical brewery applications include using compressed air for cleaning or drying bottles and cans during the filling process and for blowing out lines between batches. One particularly sensitive application is wort aeration, wherein compressed air is in contact with the product for an extended duration. In all these cases, the final quality of the beer is affected by the compressed air and the odours and particles it contains. Therefore, maintaining high-quality compressed air is crucial to ensure the integrity and taste of the brewed products.

MS-Series Compressed air preparation

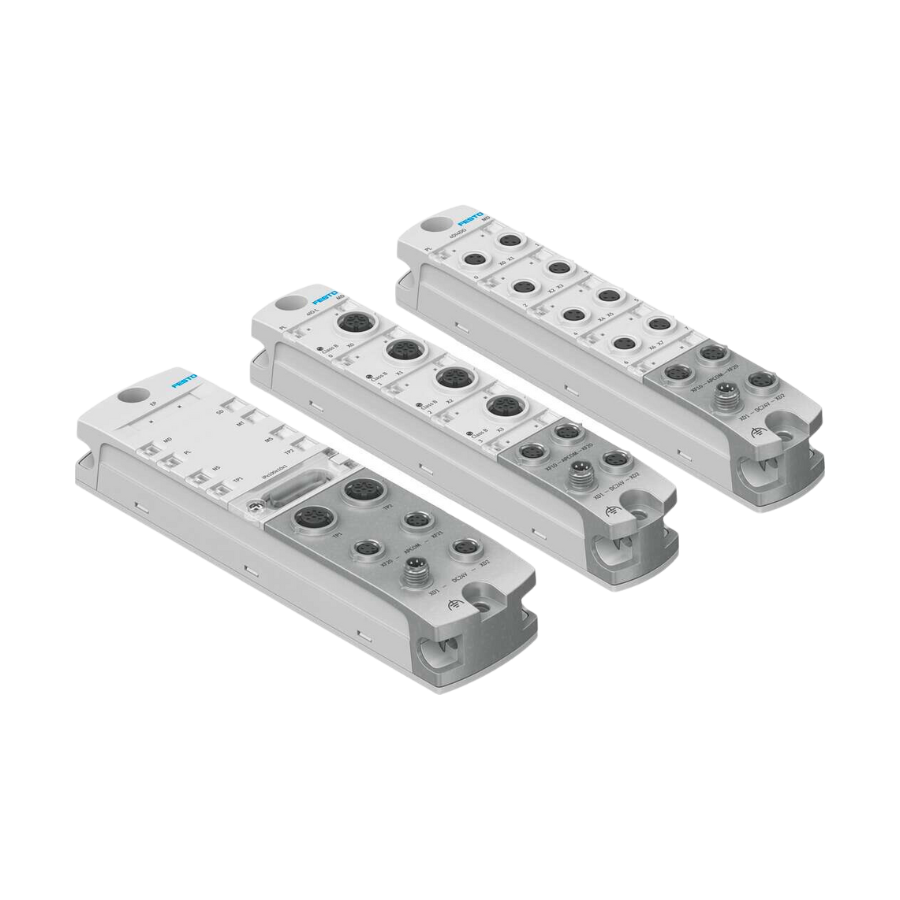

Controllers, pneumatic valves and I/O play a significant role in the breweries, providing automation, monitoring and control capabilities for several processes. Controllers can regulate the temperature needed of the equipment, contributing to the desired flavours, aromas, and characteristics of the beer. They help streamline the process by programming and executing various tasks without manual intervention, controlling the flow of liquids and gases, maintaining the correct pH levels and more.

Automation System CPX-AP-I

For over 150 years, they have been known for engineering excellence, innovation, quality and reliability. They offer comprehensive portfolio offering best-in-class transmitters for the widest range of applications. It believes in building products that allow you to measure anything and everything whether it is pressure, temperature, flow or level. In addition, you can also find electropneumatic positioners, process controllers and process recorders at Siemens.

Flow meters accurately measure the flow rate of liquids and gases, providing valuable data that allows for monitor, control and optimize operations. They help control the flow of water and regulate the ratio of liquid to grain, ensuring efficient starch conversion. Moreover, they help with the beer’s bitterness and aroma by controlling the flow of liquid into the kettle during boiling.

Flow meters are essential during fermentation, filtration and clarification processes. They provide essential data and control capabilities that enable breweries to maintain consistency, optimize processes, improve resource management, and ensure the quality of their beer. This level of precision and monitoring is vital in the highly nuanced and quality-driven world of brewing.

From cutting-edge flow meter technologies that optimize brewing processes to state-of-the-art automation systems that streamline operations, E.B. Horsman & Son can help you empower your brewery to craft the perfect pint and deliver the finest quality and consistency in every sip.

Customer Service

1.888.467.7626